Bluestreak Quality

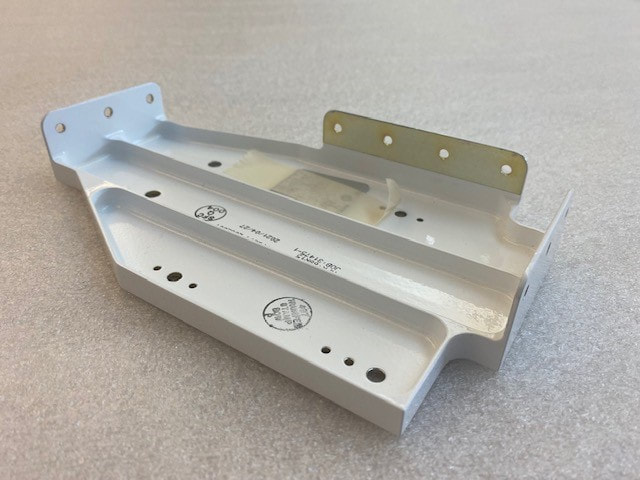

- Master job planning and routing files for each part number that include specific equipment, set-up instructions, run data and parameters inclusive of documented

- Customer specific specification, engineering requirements, key characteristics.

Verification and validation of each manufacturing operation.

- Verification and validation of in-process inspection data, statistical measures and physical property certifications and test reports

- Audit and compliance to each unique customer product requirement ensuring full compliance to customer requirements

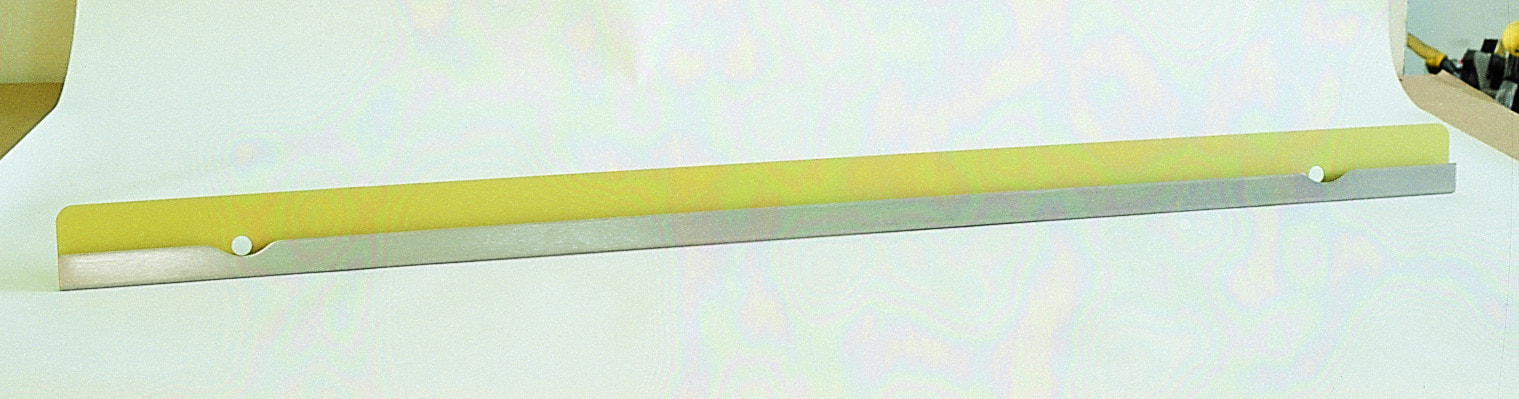

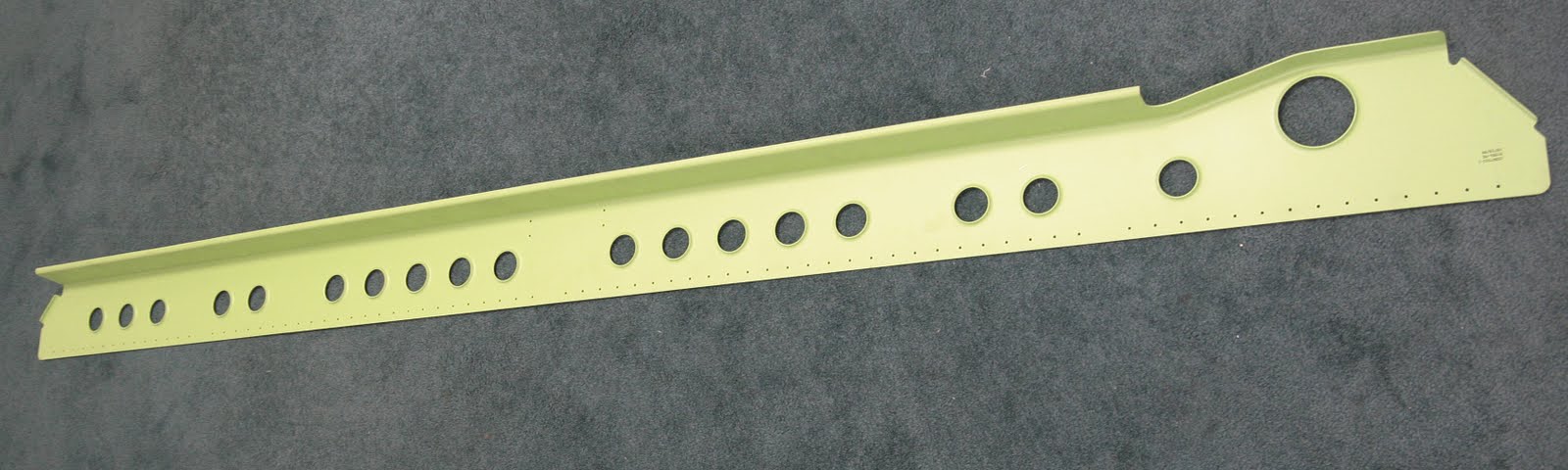

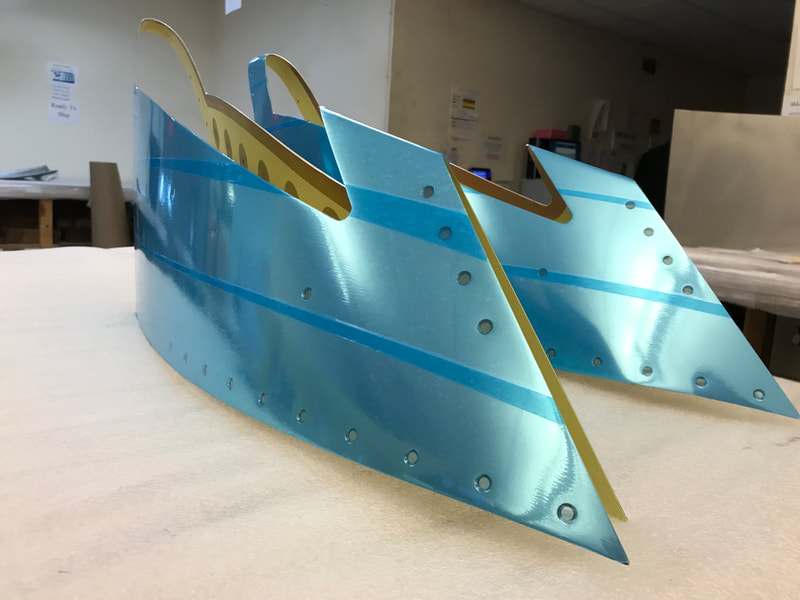

We recognize every part and situation is unique

- Vertical Integration significantly reduces the need for external support.

- State of the art technology for modeling or reverse engineering parts, related tools or legacy 2D engineering data

- 3D printing of tools

- Internal tooling department creating temporary tooling to support cost and schedule needs

- Redundant equipment specifically dedicated to Blue streak manufacturing

- Real time integrated shop control tracking and measurement to schedule and cost

- Quality is prioritized in every aspect of our manufacturing process with validation of compliance to each unique customer and product requirement

- 24 hours a day 7 days a week support team