Proven success on full-size determinant assemblies

With the continued push to optimize aircraft manufacturing and increase affordability, OEMs have started utilizing full-size determinant assembly (FSDA) in modern aircraft builds and designs.

FSDA disrupts the traditional build sequence by incorporating all features in a manufactured part in the detail state instead of the legacy method of at final assembly. This methodology has resulted in reduced fastener rework, a 75% increase in improvement in first-time engineering quality, and an 80% reduction in assembly hours.

SFC employs a defined, proven process to manufacture parts to the stringent requirements demanded by full-size determinant assemblies.

SFC Offers a Turnkey Solution

With the continued push to optimize aircraft manufacturing and increase affordability, OEMs have started utilizing full-size determinant assembly (FSDA) in modern aircraft builds and designs.

FSDA disrupts the traditional build sequence by incorporating all features in a manufactured part in the detail state instead of the legacy method of at final assembly. This methodology has resulted in reduced fastener rework, a 75% increase in improvement in first-time engineering quality, and an 80% reduction in assembly hours.

SFC employs a defined, proven process to manufacture parts to the stringent requirements demanded by full-size determinant assemblies.

SFC Offers a Turnkey Solution

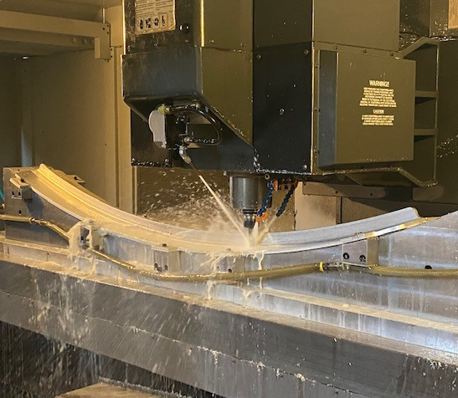

- NC programming staff in-house utilizing the latest CAM software

- In-house tool design and manufacturing

- Cutting-edge CMS equipment running the latest software operated by highly trained and proficient CMS operators.

- 3D scanning capability

- Reverse engineering

Equipment List

- Viper PRO-5210 Vertical Gantry Bridge 3 axis 197” x 82.67” x 30.71”

- Viper PRO-4210 Vertical Gantry Bridge 3 axis 164” x 82.68” x 30.71”

- Viper B-5000 Mill 5 AB 5 axis 200” x 90.5” x 39” Bridge Mill 50 Taper

- Viper B5000 Mill 5AC 5 axis 156” x 76” x 27” Bridge Mill 50 Taper

- Viper B4000 Mill 3 axis 156” x 76” x 27” Bridge Mill 50 Taper

- DMS Gantry Mill BC 5 axis 256” x 112” x 61” 20,000 RPM HSK 63 Taper

- DMS Gantry Mill BC 5 axis 372” x 132” x 49” 20,000 RPM HSK 63 Taper

- DMS Bridge Mill BC 5 axis twin table 120” x 60” x 49” 20,000 RPM BT30 Taper

- HAAS VR-11 Mill AB 5 axis 120” x 39” x 29” 12,000 RPM 40 Taper

- HAAS VF-11 Mill 3 axis 120” x 39” x 29” 8,000 RPM 40 Taper

- Akira Seiki VMC 5222 3 axis 50 x 20 x 20

- Mori Seiki MV55 3 axis 41” x 21” x 22” 5,000 RPM 50 Taper

- Romer Arm 12ft-Verisurf

- API Laser Tracker-Verisurf

- Creaform Photogrammetry

- Creaform Metra Scan 3D Scanner

- (2) Verisurf Licenses (3D Metrology Software)

- (3) Mastercam Licenses (CAD/CAM Software)

- (1) Solidworks License

- (1) Catia CATMSE-ALC License

- (1) Catia DMU License